Multi-Location Retail Rollout With One Standard

Delivery Playbook

Scaling Up Without Slipping Up

A fast-growing retail brand set its sights on expanding into 8–15 new cities in a short span. The opportunity to capture new markets was huge, but so were the execution risks. Each new store was being built by different contractors under varying site conditions – one in a sleek mall, another in a renovated heritage building, yet another in a standalone roadside location. The result? Inconsistent store quality, extended build times, and a diluted brand image. Some outlets had noticeable differences in finishes, and a few even opened late due to redoing work that wasn’t up to the brand’s standard. The client turned to Maanicare for a solution that would allow them to roll out stores like clockwork, with uniform excellence, no matter the city or site quirks. We set out to create a “one standard” approach – a repeatable model that ensured every store looked and felt unmistakably theirs, while speeding up the rollout schedule.

The Business Challenge

Problem Statement

How do you maintain a consistent brand experience and efficient timeline when building multiple stores in parallel across diverse locations? The core issue was fragmentation: each project was handled almost as a one-off, causing duplication of effort and variation in outcomes. The design intent coming from headquarters was solid, but by the time it translated through local architects, contractors, and adjustments to fit site-specific constraints, the execution drifted. The challenge was to standardize the retail build process end-to-end – from design specifications to procurement to quality checks – so that “a store is a store” regardless of where it’s built. Additionally, we needed to reduce the inefficiencies: time wasted in redesigning for each site and money wasted on rework or inconsistent materials.

Key Constraints & Complexity

Expanding with one standard in mind had to contend with several complexities:

- Varied Site Footprints – No two retail spaces were exactly alike. One location might have high ceilings and ample floor area, while another was compact with structural columns in odd places. The rollout standard had to be flexible enough to adapt to these differences without compromising the brand elements or requiring a fresh design each time.

- Local Contractors & Trades – With expansion spanning many cities, relying on a single construction team wasn’t feasible. Local contractors were engaged for speed and cost reasons, but their capabilities and understanding of the brand standards varied. We needed a way to guide and control quality among multiple execution teams remotely.

- Supply Chain & Materials – A consistent look means using consistent materials and fixtures – but sourcing those across far-flung locations is a logistical challenge. Some cities didn’t have the same suppliers; some materials had long lead times if shipped from a central warehouse. Balancing standardization with practical availability was key.

- Simultaneous Projects – The brand wanted to open stores quickly, meaning several projects would run in parallel. This raised the stakes on coordination: lessons learned or changes needed had to propagate instantly to all ongoing sites, and the central team needed visibility without physically being everywhere at once.

Maanicare’s Approach

Maanicare’s approach was to create a replicable model for store rollout – essentially productizing the process of store construction. We focused on four pillars: standardize design, streamline procurement, network the execution, and enforce quality.

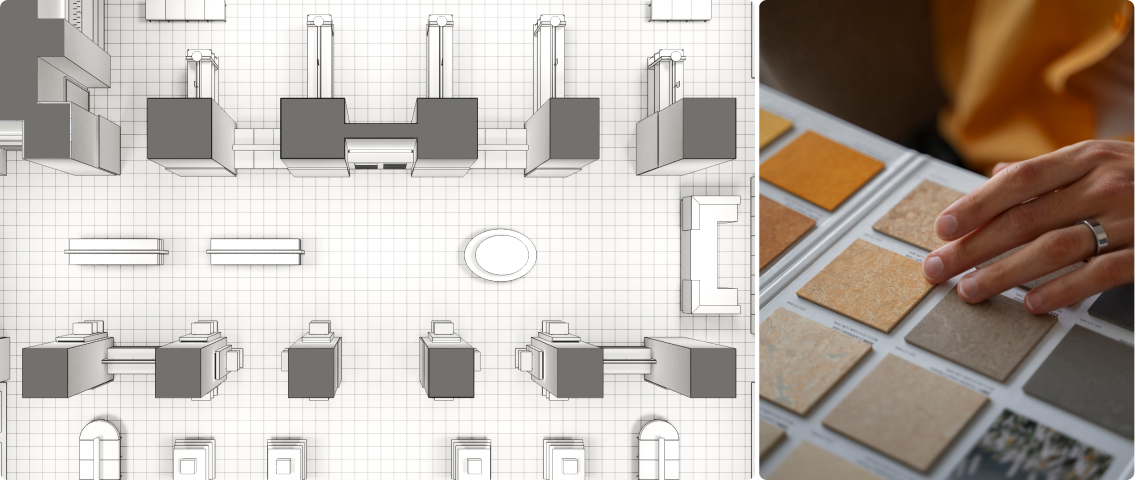

3.1 Developing the Master Design & Spec Playbook

We started by working with the client’s design team to build a Master Specification Playbook. This was more than a normal design guideline document; it was a detailed kit that included: architectural drawings and 3D renders of a prototype store, a catalog of approved materials and fixtures (down to paint codes, tile models, light fixture SKUs), and design templates for common scenarios (like how to handle a supporting column in the middle of the sales floor, or how the storefront signage adapts if the facade width is different). We essentially designed an ideal “prototype store” which could then be slightly adjusted for each site. Importantly, for each element in the design, we defined acceptable variation ranges – for instance, “if store ceiling height is under X, do A; if higher, do B” – so that local architects could adapt without losing fidelity. This playbook became the bible for everyone involved in any store project. It ensured that whether a contractor was in Mumbai or a tier-2 city, they had a clear visual and written reference of what the end result must look like and what materials to use.

3.2 Standardized BOQ and Bulk Procurement

From the master design, Maanicare derived a standard Bill of Quantities (BOQ) for a typical store. This listed every material, fixture, furniture piece, and equipment needed, along with approved brands or suppliers. We then coordinated with the client’s procurement team to set up bulk ordering agreements for key items – leveraging volume to get better prices and to ensure availability. For example, all the floor tiles for every new store might be the same model; by buying them in bulk and warehousing centrally or with a preferred vendor, we removed the risk of a local contractor substituting a different tile because “the specified one wasn’t available”. Similarly, brand elements like signage, checkout counters, display racks etc., were standardized as a “kit-of-parts” – often prefabricated at a central location. When a new store came along, these parts could be shipped and assembled, rather than built from scratch on site. This not only saved time but also guaranteed that a checkout counter in City A is identical in look and build to one in City B.

3.3 Building a Distributed Vendor Network

For execution, we identified and pre-qualified a network of contractors and vendors across the target cities. Maanicare organized briefing sessions with all these partners to walk them through the Master Playbook and expectations. In some cases, we paired a less experienced local contractor with a more seasoned site manager or clerk-of-works who had done other stores, effectively spreading expertise. We also put in place a single communication channel (like a dedicated project management portal or chat group per project) that connected all site teams with the central Maanicare coordination team. This meant that if any site encountered a challenge (say, the specified light fixture’s shipment is delayed at customs, what’s the approved backup?), they could quickly get guidance, and that guidance was visible to all so other sites could preemptively apply it if relevant. This networking of execution teams created a community of practice, turning what could have been isolated projects into a synchronized rollout program.

3.4 Remote Quality Control (QC) Mechanisms

Quality assurance was a top priority – one poorly executed store could hurt the brand. Since we couldn’t have the same supervisor physically on all sites constantly, Maanicare deployed a remote QC system. We developed a digital checklist app where site engineers would upload photos and status updates at critical milestones (for example, after wall paint, after fixture installation, after signage mounting, etc.). These were reviewed by our central quality team in near-real-time. Any deviations or concerns triggered an alert and a corrective action, which might involve a video call walkthrough or dispatching a roving quality auditor for an on-site visit if needed. We also mandated a final audit before store handover: a Maanicare quality manager (or a trained local auditor using our checklist) would physically inspect the finished store against the compliance checklist derived from the playbook – checking everything from the brightness of light levels to the alignment of the logo sign. Only when this audit was passed did we green-light the store for opening. This rigor in QC, supported by tech tools for efficiency, ensured each store met the brand’s standards despite being built by different crews.

The Solution: A “Cloneable” Store Rollout Model

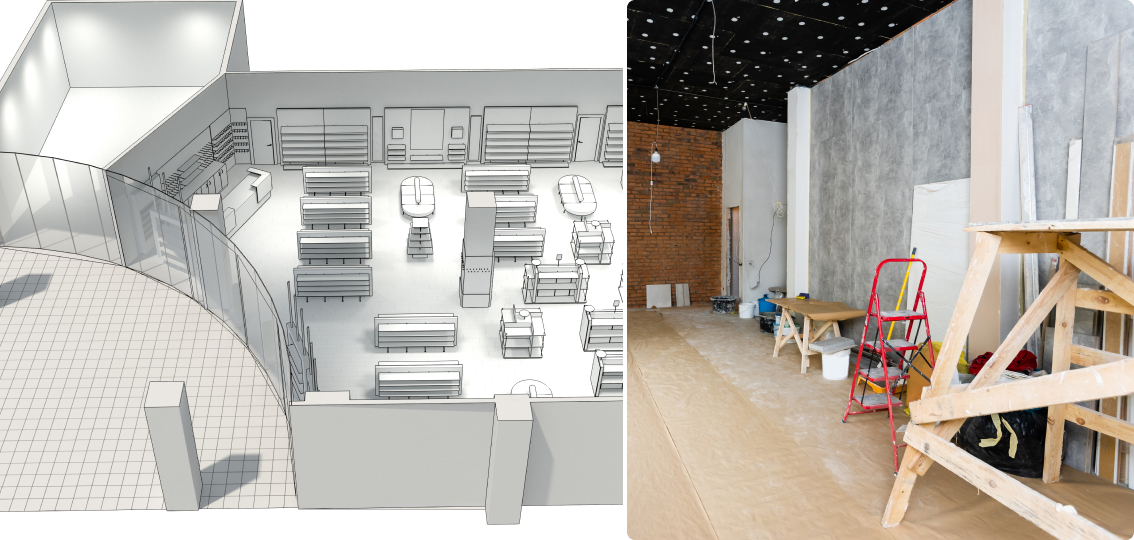

With these processes in place, opening a new store became far more predictable. It was almost like using a template – a new location came in, and much of the playbook was applied as-is, with minor tweaks for size or layout. The master BOQ and kit-of-parts approach meant local teams weren’t reinventing anything; they were assembling a well- thought-out design with known components. Decision-making was faster because so much was already decided in the prototype and playbook. Where adjustments were needed, they were done within the framework of the guidelines, so the end result still looked uniform.

Project timelines shrank. For instance, design approval per store went from several weeks of back-and-forth to just a quick localization exercise. Procurement delays dropped since materials were pre-sourced and ready to go. Construction sequences were smoother too – contractors, having done one store, knew exactly what was expected on the next, reducing their learning curve to near zero. In effect, the brand had developed an assembly line for stores – each location unique in some ways, but largely a repeatable execution of a proven model.

Impact: Faster Openings, Consistent Stores, Stronger Brand

The “one standard” rollout strategy delivered impressive results both in efficiency and brand integrity:

5.1 Accelerated Store Launches

Average store completion time dropped significantly. By some measures, the brand was able to open stores X% faster on average compared to earlier projects. This meant a tangible business advantage – each store started generating revenue sooner, and the overall expansion plan stayed ahead of competitors. The standardized timeline also helped with marketing and launch coordination; the company could plan grand openings with confidence in the construction finish dates.

5.2 Drastically Reduced Rework and Snags

With quality baked in from the start, rework was reduced by a notable Y%. Contractors following the checklist made fewer mistakes, and the remote QC caught any issues early – preventing costly tear-outs later. The punch-list (snag list) at the end of projects became much shorter, often just minor touch-ups, whereas before it might have included significant fixes. This not only saved cost but also spared management the frustration of extended project closures and budget overruns.

5.3 Uniform Brand Experience Across All Locations

Perhaps the most visible outcome was the impeccable consistency of the stores. Customers walking into a new outlet in a different city would find the same ambiance, layout cues, and quality as a flagship store. This consistency improved the brand’s reputation; it signaled professionalism and reliability. Internally, the brand’s design and marketing teams were thrilled – their vision was being realized faithfully each time. They even instituted a “brand consistency audit” for new stores, and scores on those audits improved markedly (qualitatively, it went from mixed results to uniformly high). It created a feedback loop: seeing the success of the standard model, the company gained confidence to expand further, knowing the formula worked.

5.4 Efficient Scaling and Easier Management

The rollout program’s structured nature made it easier for the client’s management to oversee multiple projects. Regular reports from the digital project platform meant they could monitor progress at a glance. Risks were flagged early. This efficiency freed the core team to focus on strategic decisions (like choosing the next city) rather than micromanaging construction details. Essentially, Maanicare’s system turned a potentially chaotic expansion into a well-oiled operation.

5.5 Strategic Impact for Maanicare

For Maanicare, this multi-location rollout program highlighted our strength in combining design standardization with operational execution. We showcased how a clever mix of planning, technology, and network management can solve a classic industry problem of inconsistent rollouts. This success positioned Maanicare as an ideal partner for any brand looking to scale their physical presence rapidly – not just in retail, but also F&B chains, bank branches, or any multi-unit expansion. It demonstrated that we don’t just build stores, we build systems that build stores, a compelling value proposition in the market.

Key Learnings

- Design Once, Deploy Many: Investing time in creating a detailed prototype and specification playbook pays off massively. It reduces downstream effort and ensures fidelity to the brand with each replication.

- Standardize What You Can, Adapt What You Must: Not everything can be identical across locations, but by defining allowable adaptations, you control variability. This balance is key to both consistency and practicality.

- Leverage Technology for Oversight: Remote QC tools and centralized communication bridged the distance between sites. In large-scale rollouts, tech- enabled oversight is essential to maintain quality without being everywhere physically.

- Train and Trust Your Network: By aligning and educating the entire network of contractors and suppliers on the brand’s expectations, you create a distributed team that can deliver collectively. Continuous communication turns individual projects into a unified program.

Executive Summary

Project

Multi-City Retail Store Rollout Standardization

Client

Undisclosed retail brand (expanding to ~10 new locations)

Scope:

Creation and implementation of a unified rollout model – including prototype store design development, standard material/fixture specifications and BOQs, building a multi-city contractor and vendor network, and establishing quality control protocols (including remote monitoring) for store fit-outs.

Maanicare’s Role:

End-to-end rollout consultant and program manager, responsible for developing standard design guidelines, coordinating procurement strategies, training local execution teams, and ensuring each store project adheres to the brand standard through rigorous checklists and oversight.

Outcome:

A faster, more reliable expansion process that delivered stores in significantly shorter time, with minimal rework, and achieved a high degree of consistency in look and quality across all locations – thereby strengthening the client’s brand presence and trust in new markets.

SHARE

SHARE